There are three Polyethylenes include HDPE (high density polyethylene), LDPE (low density polyethelene), and another type LLDPE (linear low density polyethelene). HDPE is most rigid and LDPE is softest. To achieve the moderate characteristic, LLDPE is developed. Here is simply summary of three polyethylenes.

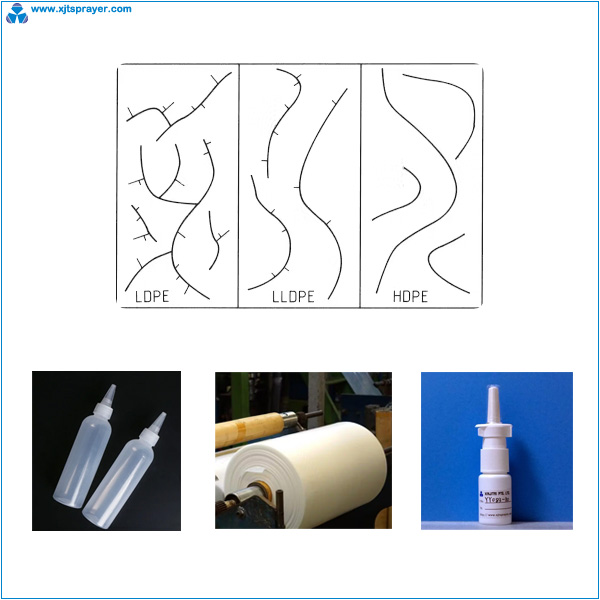

LDPE are both homopolymer of ethylene monomer, but HDPE and LLDPE are copolymers. Normally, HDPE is copolymer of ethylene and hexene, while LLDPE is copolymer of ethylene and butene. HDPE is linear. LLDPE is almost linear although it is a little branched. However, LDPE is highly branched. The degree of linearity lead to the different physical characteristics.

| HDPE | LLDPE | LDPE | |

| monomer | copolymer of ethylene and hexene | copolymer of ethylene and butene | homopolymer of ethylene |

| linearity | linear | almost linear | branched |

| density | 0.94-0.97 (g/cm3) | 0.915-0.94 (g/cm3) | 0.91-0.92 (g/cm3) |

| catalyst / initiator | catalyst Ziegler–Natta, chromium based, metallocene. | catalyst Ziegler–Natta, chromium based, metallocene. | initiator like oxygen or organic peroxide |

| pressure for production | low | low | high |

| relative mechanical characteristics | more rigid | middle | softer |

| application | hard bottles, containers, etc. | films, etc. | squeezable bottles, etc. |

Production of LDPE doesn’t use metallic catalyst. Initiator like oxygen or organic peroxide is used under high pressure. LDPE is also called high pressure polyethylene (HPPE). Therefore, no metallic residue in the final LDPE product. For productions of HDPE and LLDPE, metallic catalyst is used. However, no metallic residue is detectable in final products (MDL is 0.2 to 0.5 mg/kg).